Split Bolt Size Guide | AWG & MCM Chart for Copper and Aluminum Conductors

How to Choose the Right Split Bolt Size (AWG/MCM Guide)

One of the most common questions electricians face is: “What size split bolt should I use for these conductors?” Choosing the correct split bolt size is essential for ensuring proper conductivity, meeting NEC code requirements, and avoiding overheating or loose splices. At Conversions Tech, we manufacture UL-listed split bolt connectors in sizes ranging from 6 AWG to 600 MCM, designed for both copper and aluminum applications.

This guide will walk you through the basics of split bolt sizing, provide an easy-to-follow AWG/MCM chart, and explain common mistakes to avoid when splicing conductors.

Why Split Bolt Sizing Matters

Split bolts work by clamping down tightly on conductors to create a low-resistance, mechanically secure joint. If the connector is too small, the conductors won’t seat properly, causing arcing or overheating. If the connector is too large, the wires won’t compress securely, resulting in a loose connection.

Correct sizing ensures:

- Compliance with NEC 110.14(B) for mechanical connections.

- Maximum conductivity with minimum resistance.

- Prevention of hot spots and premature failure.

- A safe and long-lasting splice or termination.

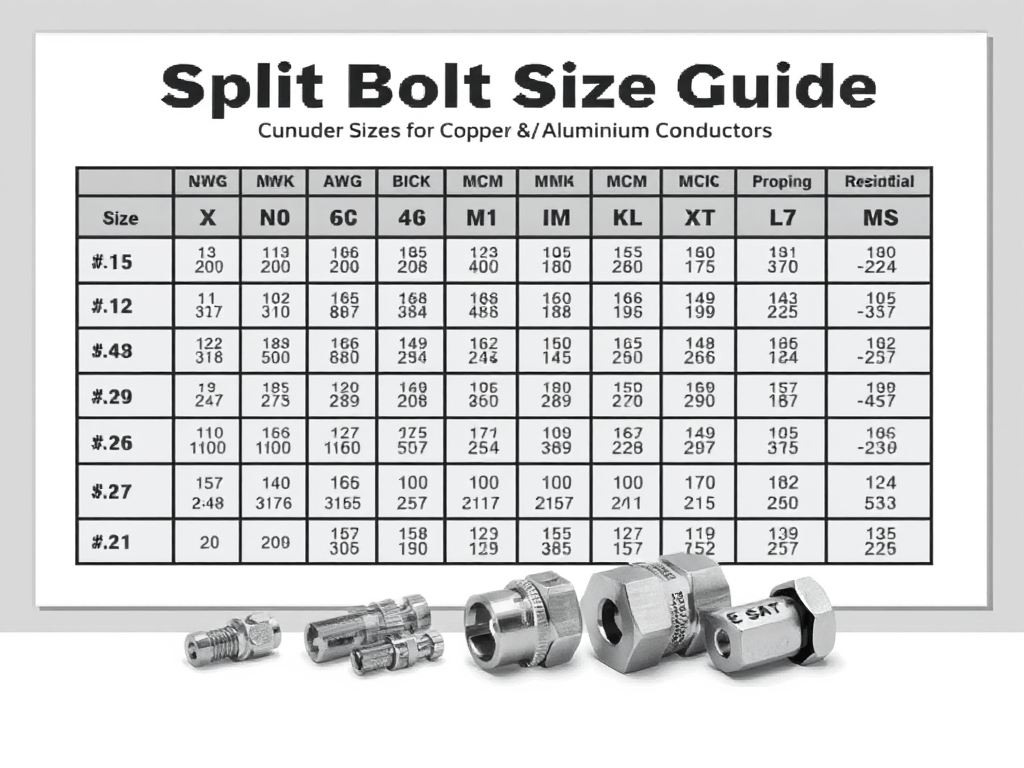

Split Bolt Size Chart (AWG & MCM)

Here is a general reference chart for selecting split bolt sizes based on conductor gauge:

| Split Bolt Size | Conductor Range (Copper) | Common Applications |

|---|---|---|

| #6 | 14 – 6 AWG | Lighting circuits, control wiring |

| #4 | 10 – 4 AWG | Residential feeders, HVAC connections |

| #2 | 8 – 2 AWG | Branch circuits, small service entrances |

| #1/0 | 6 AWG – 1/0 | Main feeders, residential service |

| #2/0 | 4 AWG – 2/0 | Commercial panels, heavy branch circuits |

| #4/0 | 2 AWG – 4/0 | Industrial feeders, switchgear |

| #350 MCM | 1/0 – 350 MCM | Large service conductors, parallel feeds |

| #500 MCM | 2/0 – 500 MCM | Utility service entrances |

| #600 MCM | 250 – 600 MCM | Heavy industrial power distribution |

👉 Browse our full range of split bolt connectors to find the exact size for your job.

Copper vs. Aluminum Conductor Considerations

Not all split bolts are created equal. When connecting copper to aluminum conductors, you should always use a tin-plated bronze split bolt to prevent galvanic corrosion. Bare copper split bolts are suitable only for copper-to-copper splices.

- Copper Split Bolts: Ideal for copper-only splices, grounding, and bonding.

- Tin-Plated Split Bolts: Required for copper-to-aluminum splicing to prevent corrosion.

Common Mistakes When Sizing Split Bolts

1. Choosing Too Small

A split bolt that is too small won’t fully seat the conductor. This leads to increased resistance and the risk of overheating.

2. Choosing Too Large

An oversized split bolt will not clamp the wire tightly enough, leading to vibration loosening, poor conductivity, and inspection failures.

3. Ignoring NEC Code Requirements

The National Electrical Code requires that connections be made with devices identified for the conductors in use. Always match the split bolt’s listed range to the conductor size being spliced.

Step-By-Step Sizing Example

Let’s say you are splicing two 2/0 AWG copper conductors in an industrial feeder circuit:

- Check the chart above → 2/0 AWG requires at least a #2/0 split bolt.

- If splicing multiple 2/0s together, move up to a #4/0 split bolt for capacity.

- Ensure the connector is UL-listed for copper and tightened to torque specs.

- Wrap the finished splice with rubber tape and vinyl tape for insulation.

Torque Recommendations

Always follow manufacturer torque specs. Over-tightening may strip threads or damage the conductor, while under-tightening reduces conductivity. Conversions Tech provides recommended torque tables with each product line.

Installation Best Practices

- Strip conductors cleanly without nicking strands.

- Position conductors evenly in the split bolt body.

- Tighten nut to rated torque values.

- Apply insulating tape if required by NEC or installation environment.

FAQs About Split Bolt Sizing

Can I use one split bolt for different conductor sizes? Yes — split bolts cover a range of AWG/MCM sizes, but always confirm the connector’s listing. What size split bolt for 4/0 copper? A #4/0 split bolt is typically used for a single 4/0 AWG conductor splice. Do I need different split bolts for copper and aluminum? Yes — use tin-plated bronze split bolts for copper/aluminum connections. Are split bolts reusable? Yes, in most cases they can be loosened and reused, provided threads and bodies are not damaged.

Conversions Tech Split Bolt Connectors

At Conversions Tech, we offer a complete line of split bolt connectors in copper and tin-plated bronze, covering sizes from 6 AWG through 600 MCM. All of our products are UL/CSA listed, manufactured from high-conductivity alloys, and designed for both splicing and grounding applications.

Need the right split bolt size?

Browse our full catalog to match your conductor size and application. From residential feeders to industrial 600 MCM splices, we’ve got the solution.