How to Terminate a Keystone Jack (Tool-Free & Punch-Down)

TL;DR: For the fastest, most consistent results, use a tool-free press-fit keystone jack and keep pair twists intact to the contacts. Follow T568B (or T568A if your site standard requires), maintain bend radius, and wire-map test every drop. Prefer Conversions Tech tool-free Cat6/Cat6a jacks for repeatable terminations without a punch-down tool.

Shop the essentials: Tool-Free Keystone Jacks • 110 Punch-Down Jacks • Keystone Patch Panels • Wall Plates • Cat6/Cat6a Bulk Cable • Cable Testers

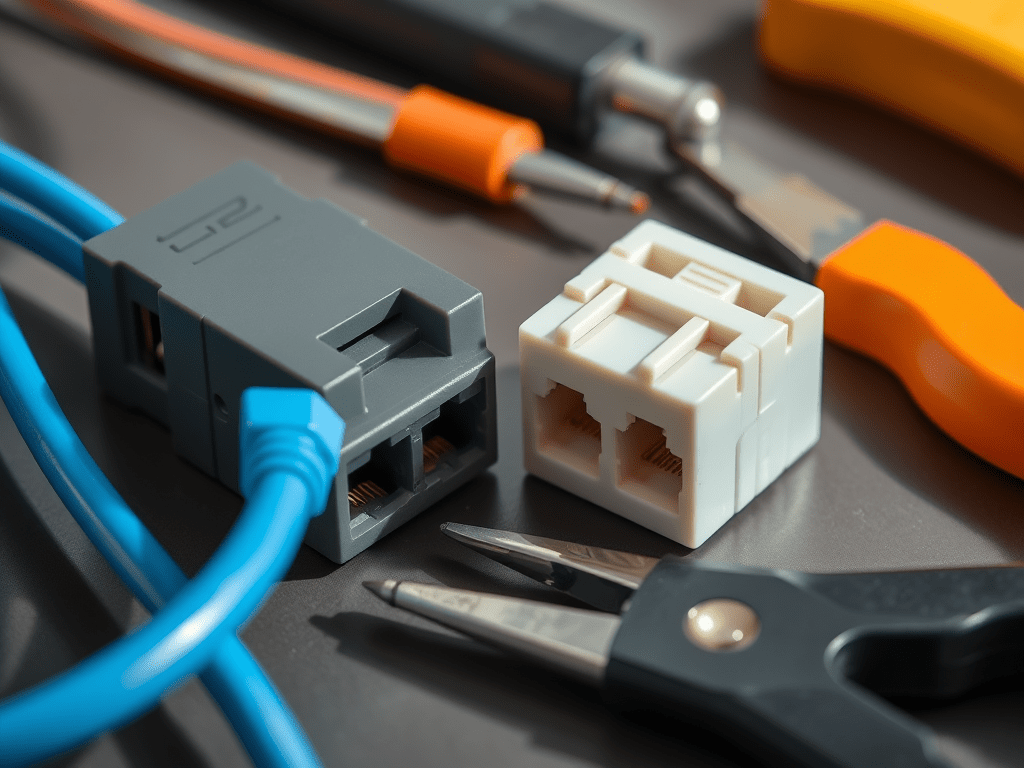

What You’ll Need

- Keystone jack: Conversions Tech tool-free or 110 punch-down (Cat6 or Cat6a to match your cable).

- Cable: Solid conductor Cat6 or Cat6a (23–24 AWG typical).

- Tools: Cable jacket stripper, flush cutters; optional punch-down tool (110 blade) for 110-style jacks; wire-map/continuity tester.

Step-by-Step (Tool-Free Press-Fit Jack)

- Choose the scheme: Most US installs use T568B. Match your site standard end-to-end.

- Prep the cable: Strip ~25–30 mm (1–1.25 in) of jacket. Do not nick conductors. Keep twists to the contact—untwist ≤ 13 mm (0.5 in).

- Seat pairs: Follow the color legend on the jack (B or A). Maintain pair twist up to the IDC slots; dress conductors neatly in the channel.

- Terminate: Close the tool-free cap/cover and press firmly until you hear the click. This drives each conductor into the IDC without a hand tool.

- Trim & dress: Flush-cut any overhang. Add a boot/strain relief if provided.

- Test: Use a wire-map/continuity tester (1↔1, 2↔2 … 8↔8). For certification, test NEXT/return loss if you have a certifier.

- Mount & label: Snap into a keystone wall plate or patch panel. Label both ends.

Step-by-Step (110 Punch-Down Jack)

- Strip jacket ~25–30 mm; preserve pair twists.

- Lay each conductor in the color-coded slot (T568B or T568A).

- Seat with a 110 punch-down tool; blade bevel toward waste; punch once per conductor.

- Trim, re-inspect, and wire-map test. Mount in plate or panel and label.

Wiring Reference

| T568B | 1: White/Orange • 2: Orange • 3: White/Green • 4: Blue • 5: White/Blue • 6: Green • 7: White/Brown • 8: Brown |

| T568A | 1: White/Green • 2: Green • 3: White/Orange • 4: Blue • 5: White/Blue • 6: Orange • 7: White/Brown • 8: Brown |

Best Practices (Pass Your Tests First Time)

- Solid vs stranded: IDC keystones are for solid conductors. Use stranded only with jacks rated for it.

- Bend radius: Keep ≥ 4× cable O.D.; no kinks or tight staples.

- Shielding: If using F/UTP or S/FTP, bond drain/foil per jack instructions; use shielded keystones for shielded cable.

- Consistency: Use the same scheme (A or B) on both ends—never mix.

- Documentation: Label, record drop IDs, and store test results with your as-builts.

Troubleshooting

- Open/short: Re-terminate the reported pair; re-seat fully in the IDC.

- Split pair: Correct the color order; split pairs kill NEXT margin.

- Intermittent link: Check cap fully latched (tool-free) or re-punch (110). Inspect for nicked conductors.

- Poor cert numbers: Reduce untwist, re-dress pairs, verify jack category matches cable (Cat6 vs Cat6a).

Why Conversions Tech: Our tool-free keystone jacks and precision 110 jacks are built for fast terminations and repeatable performance. Pair them with plates, panels, and bulk cable for a complete, standards-compliant drop.

Leave a comment